We supply woven wire mesh screen panels made of pre crimped wire, for seperating the liquids and solids in mineral industries and oil fields. According to materials, most types of crimped screens supplied for export are made of 65 Mn ( manganese) Steel and Stainless Steel. Tensile strength of the steel wire applied is generally 1200MpA. Screen edges can be hooked or framed.

Coal mine sifting screen supplied in crimped wire with hook strips.

Construction:

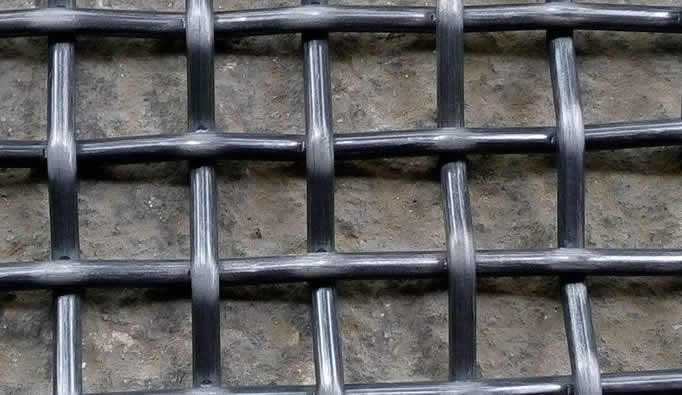

Strong crimped woven wire mesh. Firm weaving structure with square or rectangular opening.

Material: Galvanised steel, Manganese or ss wire.

Crimping styles:

Lock crimp;

Flat crimp;

Intermediate crimp;

Double crimp.

Uses: The durable crimped mesh is commonly used as screening materials of mining screen and shale shaker screen devices.

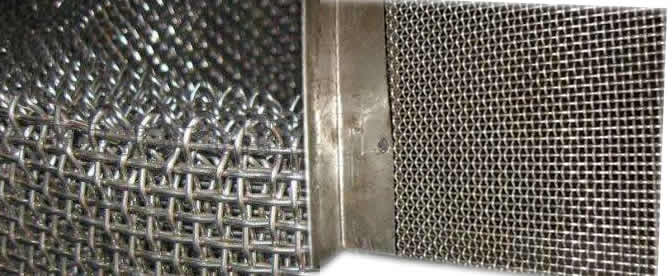

High Tensile Screen: Flat Crimped Square Mesh Vibrating Screen of Manganese 65Mn Material

Oil field shale shaker screen designed with mesh decking mounted on steel frames

This weave structure allows a great amount of open area. It is significantly more affordable and requires less maintenance than wedge wire construction mining screen options.

Wire Diameter and Panel Sizes:

Diameter of the wire used: from 1.6mm -12.7mm

Width and length of the panel can be customized.

Features of Crimped Steel Mesh Panels:

With more open area;

Lasts Longer;

The design outwears profile wire by up to ten times, and needs to be turned only 1/5 as often as profile wire;

Less Work - Less Downtime;

The long lasting screen panel mounts on a durable stainless steel frame. There is simply less work with a mesh sieve screen.

More Choices of Opening Size. Custom designs available with coming samples or drawings.

Cliclean comes with solutions! Welcome contact us with your specific orders or drawings.